Aomate brand 60T gap frame press

- group name

- C frame single crank press

- Min Order

- 1 piece

- brand name

- Xin Rui Feng

- model

- APA-60

- Nearest port for product export

- Shenzhen port, Ningbo port, Shanghai port, Qingdao port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union, Cash, Escrow

- Export mode

- Have the independent export and import right

- update time

- Wed, 11 Dec 2019 12:05:33 GMT

Paramtents

Brand Aomate

Capacity (ton) 60T

Stroke per minute(spm) 20-40/40-50

Stroke (mm) 250/150

Packging & Delivery

-

Min Order1 piece

Briefing

2.High accuracy:+/-0.01mm

3.High reliability,productivity,operational

Detailed

About APA precision punching machine :

The machine body is welded of quality steel sheel and treated by tension elimination. improve stability and reliability of precision of the machine. In order to guarantee the machine running in stable and smooth, adopts the design of symmetrical two slid board with balancer. The precision of mold adjusting up to 0.1mm,safety,reliable and convenient. Crank,gear,connect bar are oxidized hardening and milled ,having super comprehensive mechanical performance and durable function. Reasonable structural design is convenient for automatic production and line production. Used reliable high intensity clutch/brake and twin eletromagnetic valve, overloading protector can guarantee safe production all-around.

Product Features;

1.Reliability;

High rigidity, low integrated clearance, small changing in mold height,

small deviation of dynanmic center, the mold life in large scale, small transfiguration for press

2.Productivity;

High precision processing, high efficiency operation, machine to ensure products of high quality

3. Operational;

Facilitate the operation of implementation, fixed locking type six-surface guide way, cutting low-noise, safe and reliable operating state

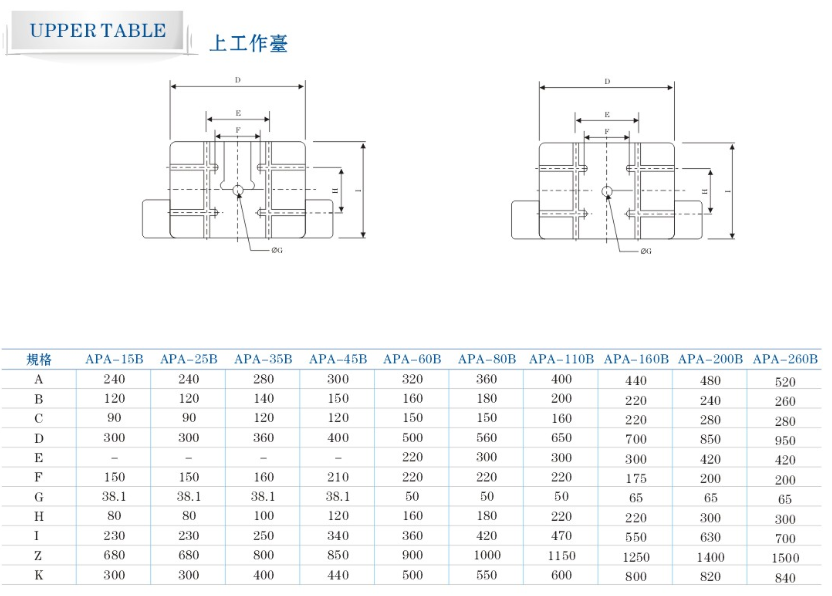

Technology Informations & Specification

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

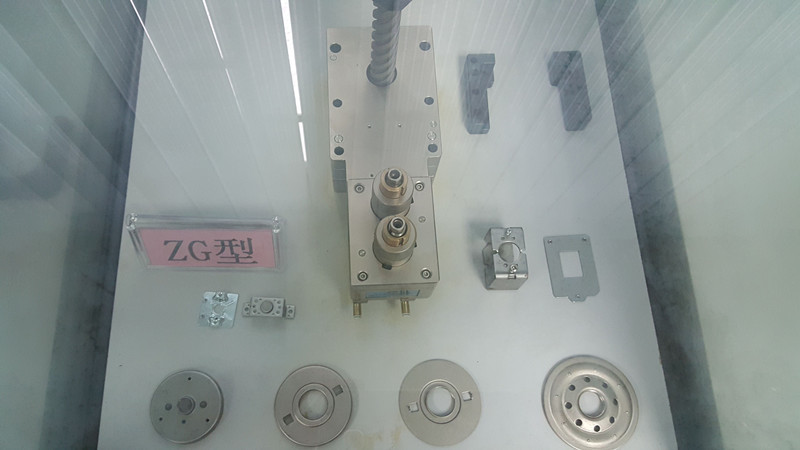

Accessories

| Standard Unit | Optional |

| Inverter | Automatic lubrication system |

| Hydraulic over-load protector | Pneumatic die cushion device |

| Manual slide adjust device (APA below 60B) | Foot switch |

| Automatic slide adjust device (APA60B or more) | Fost mdd change device (Die lifter, clamp and die arm sepjes) |

| Main motor (adjustable) | Slide knock-out device |

| Die height indicator (APA below 60B) | Photo-electronic safety device |

| Automatic die height indicator (APA60B or more) | Feeder |

| Balance device | Uncoiler |

| Rotary cam switch | Leveler |

| Crank angle indictor | Robot hand |

| Electrical stroke counter | Die room light |

| Air source receptacle | Touch pad (preset, total counter) |

| Against over-run safety device | Electrical slide adjust device (15-60T) |

| Air ejector | |

| Misfeed detection consent | |

| Power supply | |

| Anti-vibration pad | |

| Maintenance tool box | |

| Operation manual |

Key components list with brand

| No. | Key Components List | Brand |

| 1 | Motor | TECO,Taiwan |

| 2 | Inverter | Yaskawa |

| 3 | TOYOOK | MAC,America |

| 4 | MultistageSwitch | Fuji,Japan |

| 5 | Solenoid valve | MAC,America |

| 6 | Pressure switch | Fuji,Japan |

| 7 | Air switch and external parts | Fuji,Japan |

| 8 | Switching power supply | Fuji,Japan |

| 9 | Grease seal | SKY,Japan |

| 10 | Hydraulic overloading protection device | Kingair,Taiwan |

| 11 | Manual slide adjustment device | Kingair,Taiwan |

| 12 | Electric slide adjustment device | MAC,America |

| 13 | Main motor(speed adjustable) | Kingair/TECO |

| 14 | Mechanical die height indicator | Jinsong |

| 15 | Electric die height indicator | Jingsong |

| 16 | Slide and mould balancing device | Kingair |

| 17 | Crank Angle Indicator | Kingair |

| 18 | Counter | Guangqi,Taiwan |

| 19 | Air source Receptacle | Fuji,Japan |

| 20 | Over-run Safety Device | Fuji,Japan |

| 21 | Jet air device | Kingair,Taiwan |

| 22 | Filter | SMC,Japan |

| 23 | Pressure regulating valve | SMC,Japan |

| 24 | Atomized lubricator | SMC,Japan |

| 25 | Manual grease pump | Ishan,Taiwan |

| 26 | Bearing | NSK,Japan |

| 27 | Clutch | OPMI |

| 28 | Swith button | Fuji,Japan |

| 29 | Crank | Edmund |

| 30 | A set of assitant tools | WIGA,Taiwan |

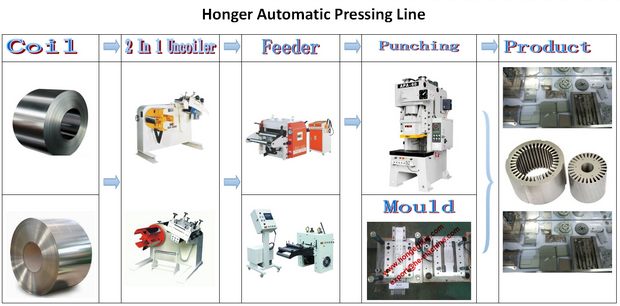

Auto Pressing Line Drawing

Factory scene:

Hong-Er Online Contact Way:

email:export..........com

tel: 0086 755 28372363

fax: 0086 755 28372353